Cell Discharge Station

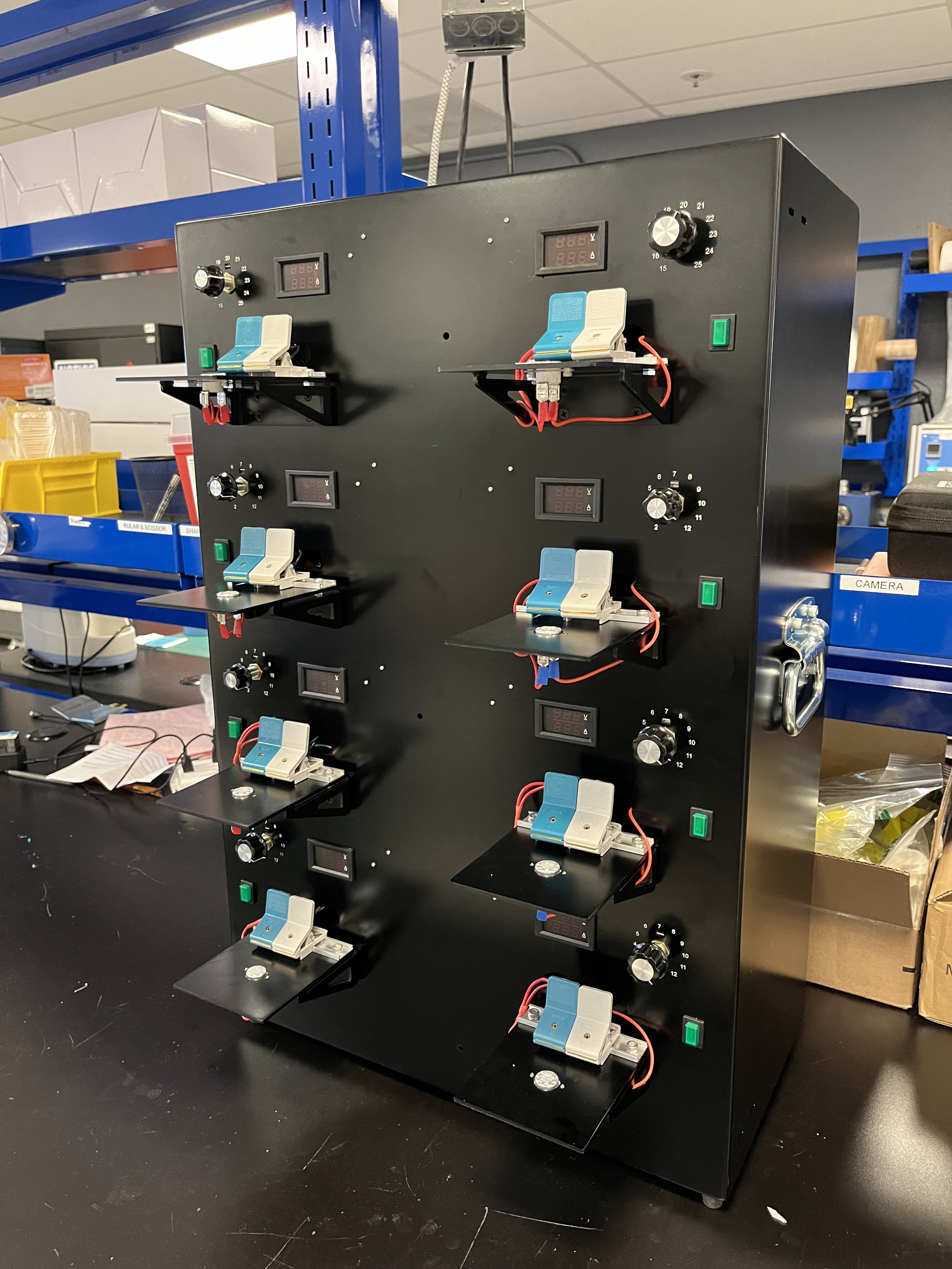

A robust solution to scale the discharging of experimental pouch cells. The project prioritizes efficiency, allowing users to simultaneously discharge 8 cells at independent rates and down to user-specified voltages. The project also prioritizes safety, implementing hardware to prevent thermal runaway, direct shorting, and over-discharging.

3880 mAh pouch cell connected in series with a 10 Ohm potentiometer

Context

In Summer of 2024, I worked at a battery startup called Anthro Energy. To dispose of experimental cells, they first needed to be discharged to a safer voltage. The baseline apparatus for discharging was a potentiometer wired in series to the positive and negative tabs of their cell. This was inefficient for a few reasons:

Users could only discharge one cell at a time

Users needed to wire a multimeter in parallel or series to know the voltage or current flow at a given time

Users would need to check cell intermittently due to lack of live feedback

Cell would discharge to zero voltage if cell was left unchecked or forgotten, risks gas generation

Designing & Prototyping

Primary considerations for prototyping were to optimize the following:

Machine Footprint — the product would need to fit in a standard fume hood.

Safety Features — thermal runaway, shorting, over-discharging, and fire risk were primary concerns

Volume — with safety and space as constraints, goal was to discharge as many cells as possible both simultaneously and independently

Stability — Clipping in a cell took quite a bit of force, so it’s important that cell platforms were designed with significant forces in mind

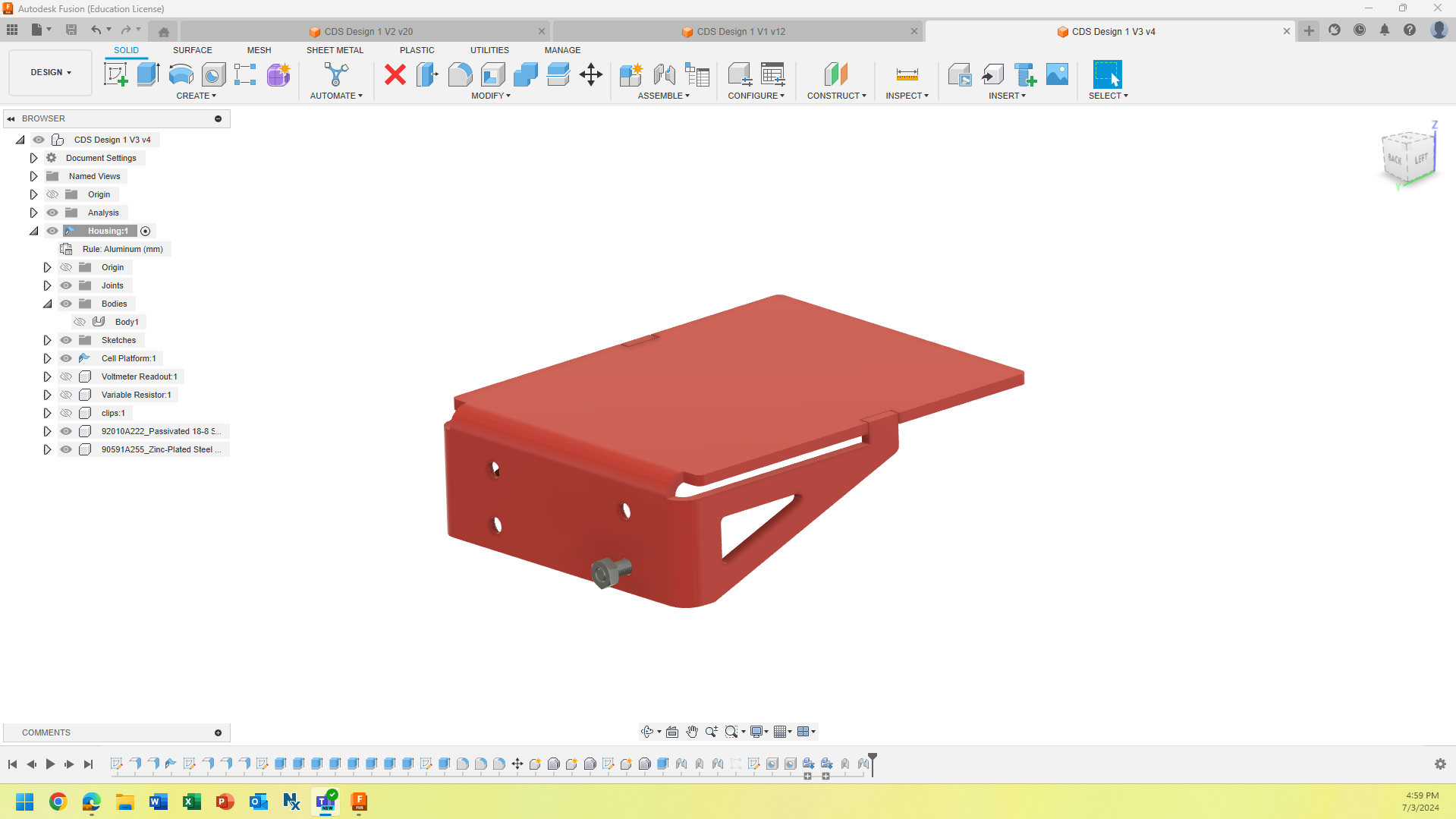

FORM: Three different orientations, each prioritizing a different design consideration.

Stacked Design: prioritizes volume.

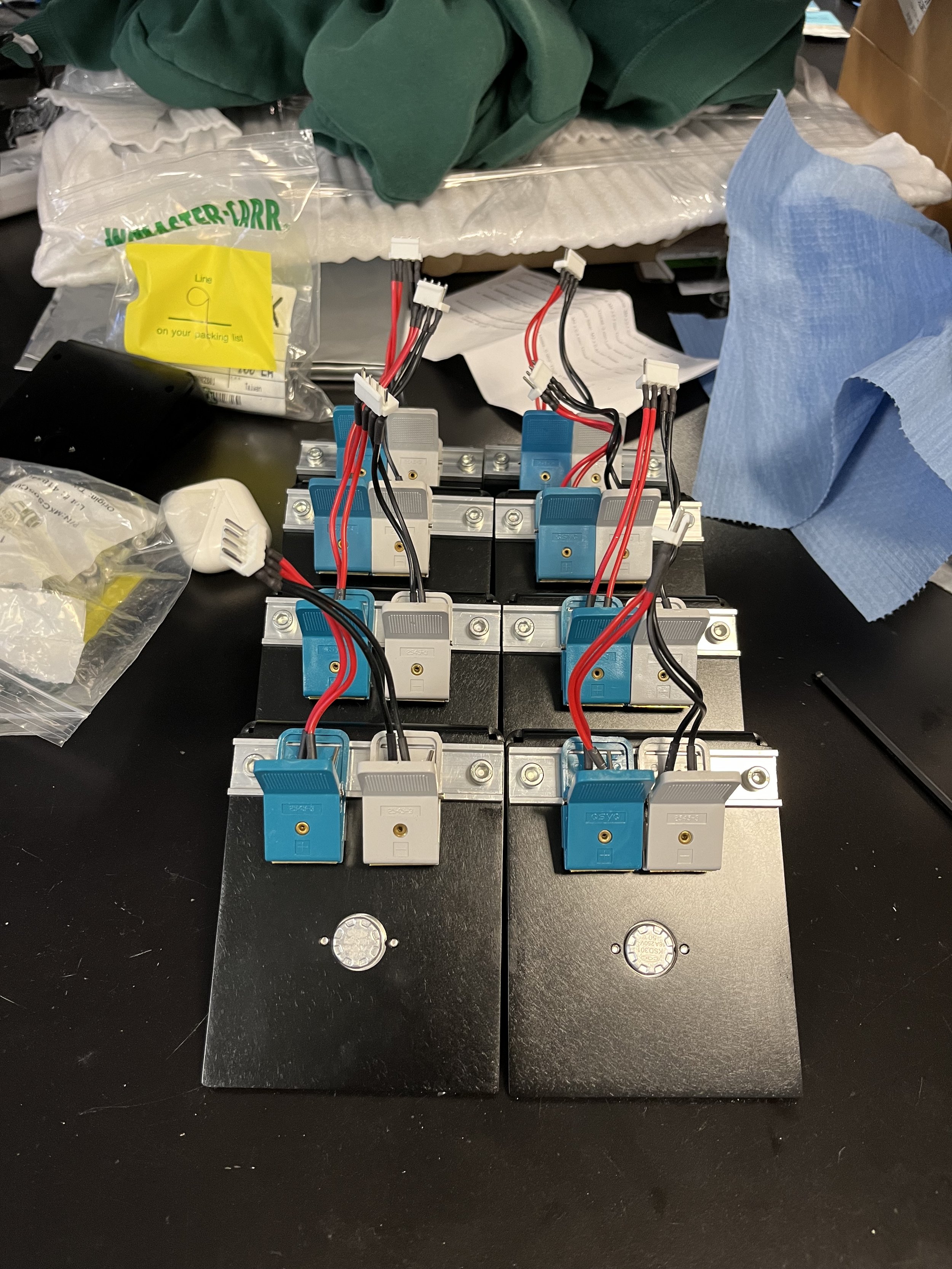

All components with mock wiring

Wired one to verify wiring works as intended

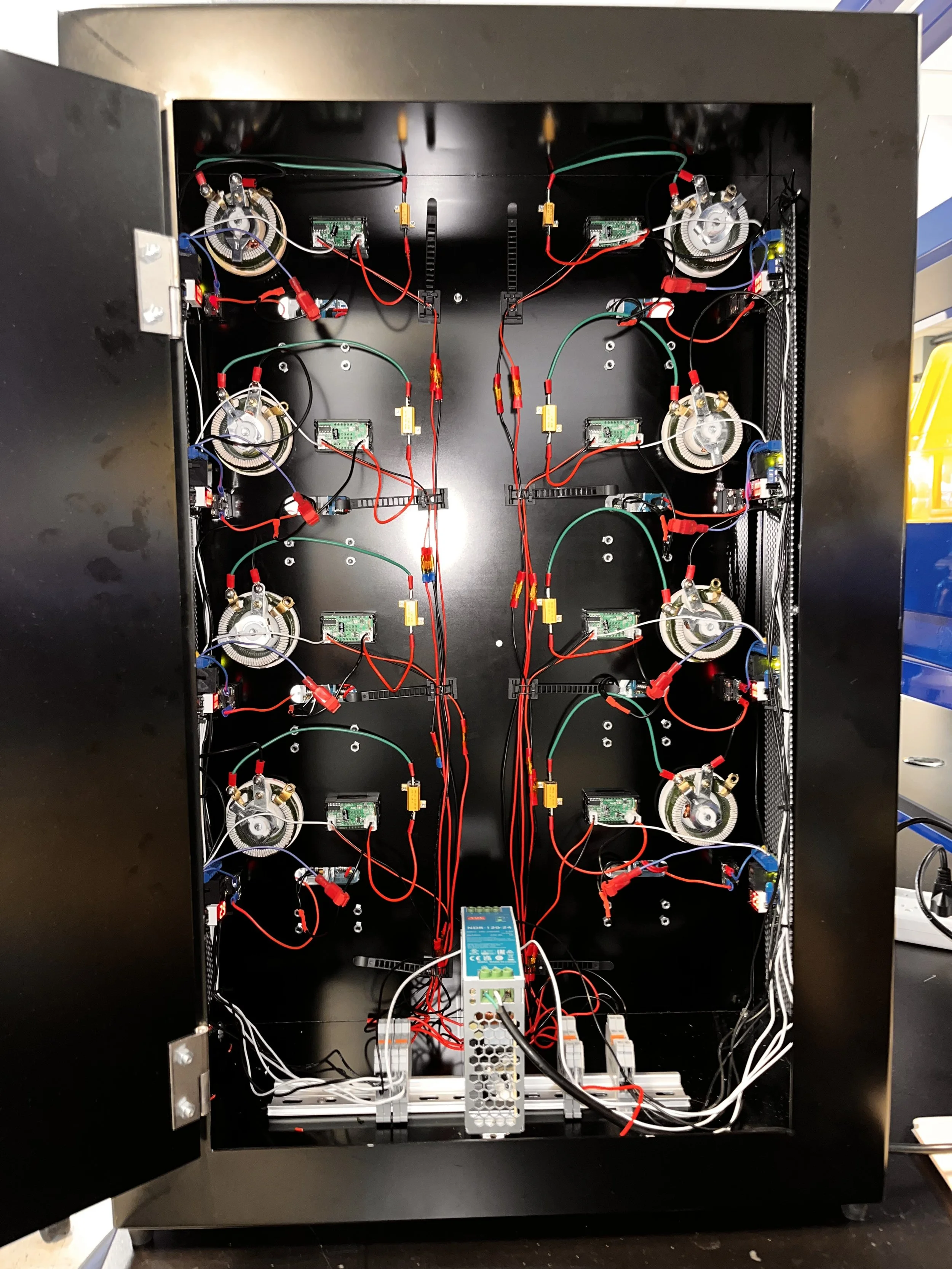

Electrical Components

Green Pushbutton - ensures that a cell doesn’t discharge unless a user intends for it to discharge

Thermal Fuse - designed to be in contact with a discharging cell, will open circuit if cell exceeds 50 degrees celsius

Power Resistor - wired in series with cell + potentiometer to establish a minimum resistance. This component is stored internally so it cannot be tampered with. This ensures that the tabs of the cell never short directly.

Potentiometer - used for fine adjustment on the resistance, enables the user to discharge at different C-rates

Terrace Design: Prioritizes safety.

Dock Design: Prioritizes stability.

Designed the platforms with user interface points: cell tabs, potentiometer, voltmeter display

Platform designed with built-in gussets

Material Selection

Housing designed to be made out of sheet aluminum. The primary components would be the rectangular prism body (1 piece) and N platforms that fasten to the body. Chose sheet aluminum for the following reasons:

relatively cheap and lightweight material

relatively small cantilever acting on platforms, 3 millimeter aluminum should withstand

could be easily anodized, for extra protection against shorting and thermal runaway

24V Voltage Relay - wired in parallel and reads the voltage of the discharge circuit. If the voltage of the cell drops below a lower voltage limit, it will stop discharging. If the voltage of the cell exceeds an upper voltage limit, the cell will begin to discharge. These limits can be set by the user (ie. 2.5V - 3V). This relay allows cells to cyclically discharge to a desired minimum voltage independently.

Voltmeter Display - wired in parallel and series to display the live voltage and current while a cell discharges.

24V Power Supply - Powers the relay and the voltmeter

Assembly

Takeaways / New Knowledge

Taught myself how to solder

Gained intuition for wire management

Results and Lessons

Results

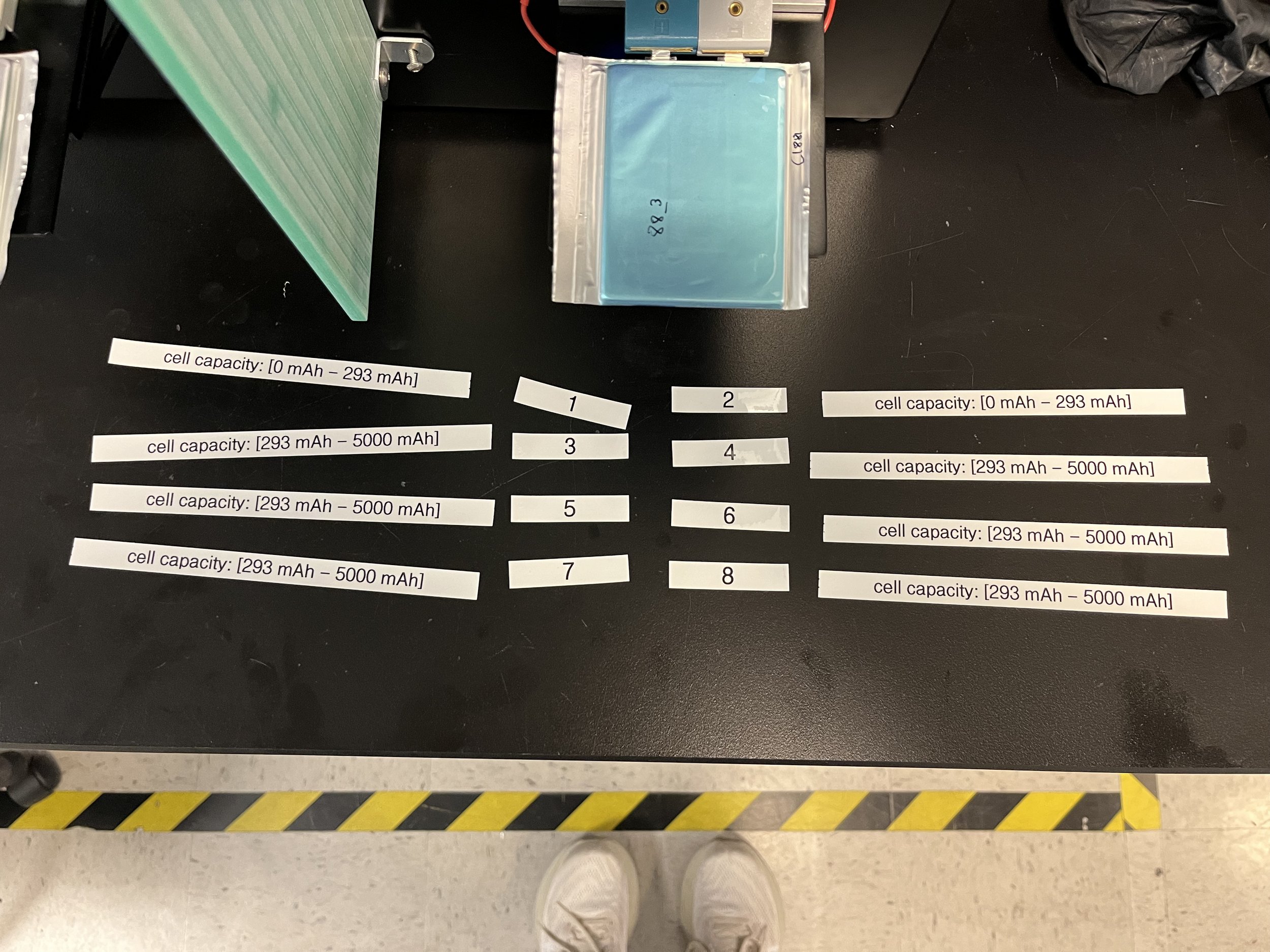

The Discharge Station can cyclically discharge 8 cells of varying capacity independently and simultaneously.

The station can accommodate a wide range of cell capacities (200 mAh to 5000 mAh).

A user can hook up a cell into one of the platforms, set the proper resistance that corresponds to a desired discharge rate, press the green button, and walk away indefinitely. The cell will cyclically discharge to 2.5V and automatically turn off once it does.

Features like the thermal fuse, garolite partition, power resistors, and fully-anodized aluminum body and platforms ensures that users are safe from heat and fire danger.

The cell discharge station allows the user a 700% increase in discharging capability as well as tremendous improvements towards safety and feedback.

Lessons

Plan for lead times. When planning a project or multiple projects that overlap, it’s important to consider machine shop lead times and incorporate those lead times in the schedule. That way, one can still be productive instead of waiting for a shipment.

Limit fastener variety. I found myself ordering screws and bolts ranging from M2 to M6 as a product of uninformed design choices towards the beginning. If you can, design to use a lot of one type of screw. It will save money and assembly time.

Account for Misuse / Abuse Cases. Luckily, I didn’t witness any direct misuse or abuse cases, but it’s important to design with the idea that people won’t understand how to use it properly. Installing failsafes like a minimum resistance or a power button are effective in taking the power to make mistakes out of the hands of the user.